The Carel Controller is a compact electronic device, similar in size to a standard thermostat, designed for efficient management of chillers and heat pumps in HVAC systems.

Overview of the Carel Controller

The Carel Controller is a compact electronic device designed for managing HVAC systems, including chillers and heat pumps. It offers advanced control functions, such as compressor and fan management, defrost cycle control, and temperature regulation. The controller supports customizable parameters to meet specific system requirements. With the ability to integrate with Carel apps, it simplifies configuration and monitoring. Suitable for various applications, it ensures efficient and reliable operation. The user manual provides detailed guidance for setup, operation, and troubleshooting, ensuring optimal performance and safety.

Importance of the User Manual

The user manual is essential for understanding and correctly operating the Carel Controller. It provides detailed instructions for installation, configuration, and troubleshooting, ensuring optimal performance. The manual outlines safety guidelines to prevent malfunctions and hazards. By following the manual, users can customize parameters and leverage advanced features effectively. It also serves as a reference for resolving common issues, minimizing downtime. Adhering to the manual ensures compliance with manufacturer recommendations, safeguarding the system and user. Proper usage, as described, guarantees efficient and reliable operation of the Carel Controller.

Installation and Setup

The Carel Controller’s installation requires careful hardware setup, following wiring guidelines, and adhering to electrical specifications. Proper replacement and setup ensure optimal functionality and safety.

Hardware Installation Steps

Handle the Carel Controller with care to prevent damage. Mount it on a DIN rail, ensuring proper alignment. Connect wires according to the wiring guide on the control label. Avoid assuming previous wiring configurations. Secure all connections tightly to prevent loose contacts. Refer to the user manual for specific installation instructions tailored to your model. Ensure the controller is installed in a safe, dry environment to maintain optimal performance and longevity.

Wiring Guidelines

Follow the wiring guide provided on the control label to ensure correct connections; Use appropriate gauge wires to avoid resistance issues. Connect power supply lines securely, adhering to electrical specifications. Ensure all ground wires are properly connected to prevent malfunction. Double-check each connection before powering up. Refer to the technical manual for detailed diagrams and specific wiring instructions for your Carel Controller model. Incorrect wiring may lead to operational issues or damage to the device.

Electrical Specifications

Consult the label on the controller for specific electrical specifications, including voltage, current, and power ratings. Ensure all connections comply with these specifications to avoid damage. Use appropriate power supplies and grounding to maintain safe operation. Refer to the technical manual for detailed electrical requirements and safety guidelines. Proper adherence to these specifications ensures optimal performance and longevity of the Carel Controller. Always verify ratings before installation to prevent potential electrical hazards or system malfunctions.

Configuring the Controller

Configuration involves customizing parameters to suit specific HVAC system needs. Use Carel apps or programming keys for precise setup. Press and hold the SET key to adjust settings.

Customizing Parameters

Customizing parameters on the Carel Controller allows users to tailor settings for optimal performance. Users can adjust temperature setpoints, defrost cycles, and alarm thresholds. The controller supports up to six customizable parameter sets, enabling flexibility for different operational needs. Adjustments can be made using the device’s interface or through Carel apps, ensuring precise control over refrigeration systems. Proper customization ensures efficiency and prevents malfunctions, aligning with the system’s specific requirements. Always refer to the user manual for detailed guidance on parameter customization.

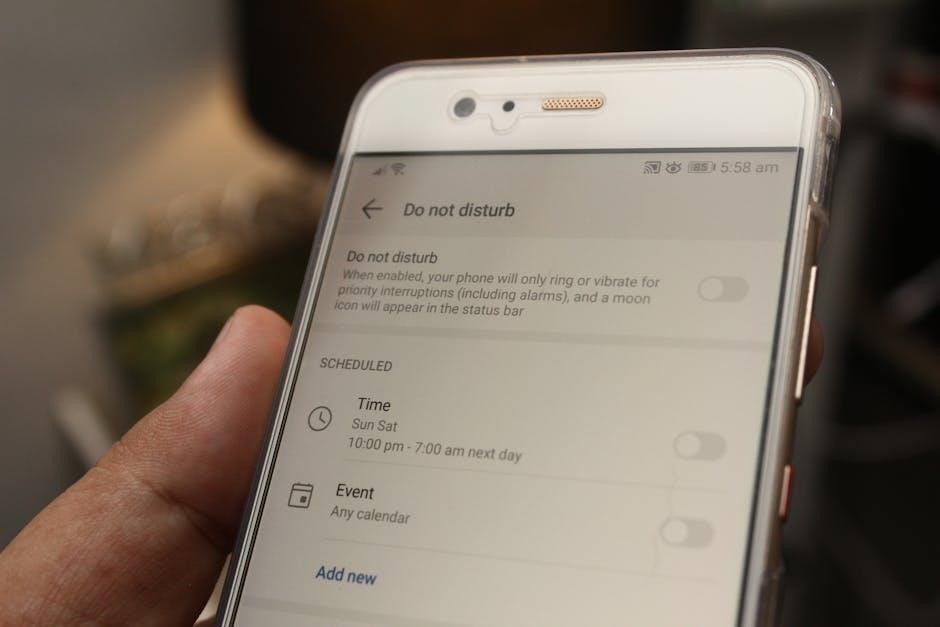

Using Carel Apps for Configuration

The Carel apps provide a user-friendly interface for configuring the controller, enabling easy customization of parameters. These apps allow users to adjust settings, monitor real-time data, and perform firmware updates remotely. Key functions include parameter adjustment, defrost cycle management, and alarm configuration. The apps also support the transfer of operating parameters to connected controllers, ensuring seamless integration. By leveraging these tools, users can optimize their refrigeration systems efficiently. The apps are compatible with various Carel devices, making them a versatile solution for advanced system management and control.

Operating the Controller

The Carel Controller operates in normal and advanced modes, managing defrost cycles, compressor control, and alarm systems. It ensures efficient performance and precise temperature regulation in HVAC systems.

Normal Operation Mode

The Carel Controller operates in Normal Operation Mode to manage HVAC systems efficiently. This mode ensures precise temperature regulation, compressor control, and condenser fan operation. Users can adjust setpoints using arrow keys, with changes applied quickly. The controller also monitors system parameters continuously, ensuring optimal performance. Alarms are triggered if predefined conditions are breached, providing real-time notifications. This mode is designed for straightforward operation, making it ideal for standard applications. It integrates seamlessly with refrigeration systems, offering reliable control and minimizing energy consumption. The Normal Operation Mode is the default setting for everyday use, ensuring smooth and efficient system management.

Advanced Operation Modes

The Carel Controller offers advanced operation modes for specialized applications, including custom defrost cycle management and enhanced system control. These modes allow users to tailor operations to specific needs, such as managing multiple defrost outputs or integrating with humidification systems. Advanced modes enable precise control over components like compressors, fans, and pumps, ensuring optimized performance. Customizable parameters and app-based configurations further enhance flexibility. These modes are ideal for complex HVAC systems, providing advanced monitoring and control capabilities. They ensure energy efficiency and system reliability in demanding environments, making them suitable for industrial and large-scale applications. Advanced operation modes require proper setup for optimal functionality.

Defrost Cycle Management

The Carel Controller features advanced defrost cycle management, enabling efficient ice buildup prevention on evaporators. It supports multiple defrost outputs and custom schedules, ensuring optimal system performance. The controller uses temperature probes to monitor conditions and initiate defrost only when necessary. Defrost modes include continuous cycles and adaptive timing based on system demands. Pressing specific key combinations can manually activate or override defrost cycles. This feature ensures energy efficiency and prevents unnecessary operational interruptions. Advanced defrost management protects equipment and maintains consistent refrigeration performance, making it ideal for industrial and commercial applications requiring precise temperature control.

Alarm Systems and Notifications

The Carel Controller incorporates an advanced alarm system that monitors system performance and triggers notifications for anomalies. Users can configure alarm variables, set priorities, and enable controls to address issues promptly. The system logs alarm events, providing a detailed history for troubleshooting. Notifications ensure timely interventions, minimizing downtime. Configurable alarm settings allow customization to suit specific applications. The controller also integrates with external alarm devices, enhancing safety and operational reliability. This feature-rich system ensures comprehensive monitoring, enabling swift responses to critical conditions and maintaining optimal operational efficiency.

Monitoring and Maintenance

Regular monitoring of the Carel Controller ensures optimal performance and longevity. Users can track key parameters like temperature, humidity, and system status in real-time. Customizable dashboards provide clear overviews, enabling quick identification of potential issues. Scheduled maintenance routines, such as checking electrical connections and updating software, are essential for smooth operation. The controller also supports data logging, allowing users to review historical performance and plan proactive maintenance. Proper monitoring and maintenance practices help prevent malfunctions and extend the lifespan of the system, ensuring reliable operation in HVAC applications.

Monitoring Parameters

The Carel Controller allows users to monitor essential parameters such as temperature, humidity, and system status in real-time. These parameters can be customized to suit specific applications, ensuring precise control over HVAC systems. The controller features advanced data logging capabilities, enabling users to track historical performance and identify trends. Alarm systems provide notifications for deviations from setpoints, ensuring timely interventions. By continuously monitoring these parameters, users can optimize system efficiency, reduce energy consumption, and maintain consistent environmental conditions. Regular review of monitored data helps in proactive maintenance and troubleshooting, ensuring reliable operation.

Scheduled Maintenance Tips

Regular maintenance is crucial to ensure optimal performance of the Carel Controller. Users should inspect wiring and connections periodically to prevent issues. Cleaning sensors and checking calibration ensures accurate readings. Updating software and firmware is essential for accessing new features and improvements. Reviewing alarm logs helps identify recurring issues early. Scheduling routine checks of system parameters, such as temperature setpoints and defrost cycles, maintains efficiency. Replacing worn components promptly prevents unexpected downtime. Following these tips ensures reliable operation, reduces energy consumption, and extends the lifespan of the controller. Regular maintenance also helps prevent malfunctions and ensures compliance with safety standards.

Troubleshooting Common Issues

Common issues include incorrect parameter settings or sensor malfunctions. Check wiring connections, defrost cycles, and alarm configurations. Refer to the manual for detailed diagnostic steps and solutions.

Identifying and Solving Common Problems

Common issues with the Carel Controller include incorrect parameter settings, sensor malfunctions, or wiring errors. Start by checking all connections and ensuring sensors are functioning properly. Review alarm configurations to identify fault codes, which provide clues about the problem. Refer to the manual for troubleshooting guides tailored to specific error messages. If issues persist, reset the controller or reload default parameters. For complex problems, consult the technical support team or use Carel’s diagnostic tools for advanced solutions. Always follow safety guidelines when performing repairs or adjustments.

Advanced Features

The Carel Controller offers specialized control functions, including advanced defrost cycle management and integration with Carel apps for enhanced configuration and system optimization capabilities.

Specialized Control Functions

The Carel Controller offers advanced control capabilities, including managing a second defrost output linked to a third probe (S3) for precise temperature regulation. It also supports control of compressors, condenser fans, and water pumps for both evaporators and condensers. Additionally, it regulates anti-freeze heaters and alarm signal devices, ensuring comprehensive system management. The controller is compatible with the Carel E2V electronic valve and PWM valves, allowing for precise modulation of refrigerant flow. These specialized functions enhance system efficiency and adaptability, making the Carel Controller a versatile solution for complex HVAC applications.

Safety Guidelines

Always handle the Carel Controller with care, avoiding incorrect operations that could cause malfunctions. Follow all safety regulations and guidelines in the user manual to ensure safe operation and prevent potential hazards or damage to the device.

Safe Handling and Operation Practices

Handle the Carel Controller with care to prevent damage. Always follow the safety guidelines outlined in the user manual to ensure proper installation and operation. Avoid exposing the device to moisture, extreme temperatures, or physical stress. Before performing any maintenance, disconnect the power supply to prevent electrical shocks. Use appropriate tools and wear protective gear when working with electrical components. Never attempt to modify or repair the controller yourself, as this could lead to malfunctions or safety hazards. Ensure all connections are secure and meet the specified electrical standards.

The Carel Controller is a sophisticated device designed to optimize HVAC system performance, offering advanced features like defrost cycle management and customizable parameters. Proper use requires adherence to the user manual, ensuring safe and effective operation. Users are advised to follow installation, configuration, and maintenance guidelines to avoid malfunctions. Regular monitoring and timely troubleshooting are essential for longevity. By leveraging the controller’s capabilities and referring to the manual for guidance, users can maximize efficiency and reliability in their applications. Always prioritize safety and correct handling to maintain optimal functionality.